Scramjet

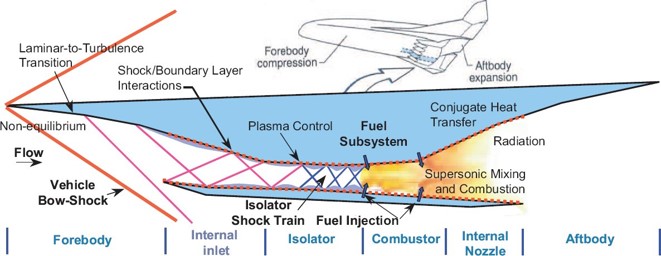

Schematic of Scramjet Vehicle Courtesey of NASA.govleft and RFL Hypersonic Vehicle Prototype right

Inlet Design for Hypersonic Vehicles

The primary function of the inlet is to efficiently capture and compress incoming air before it enters the propulsion system, ensuring optimal performance and stability.

The shockwave formation at the inlet is sensitive to flight conditions. Therefore, designing inlet that has wide operation range(e.g. Altitude, cruise Mach number, AoA) with high performance is crucial for operating supersonic combustors.

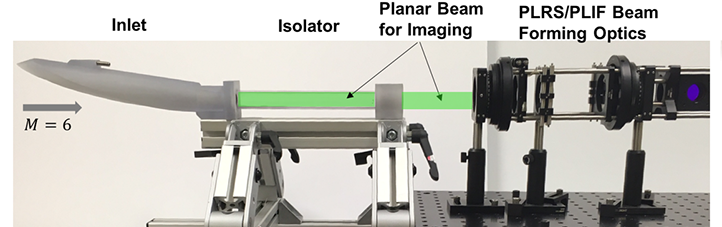

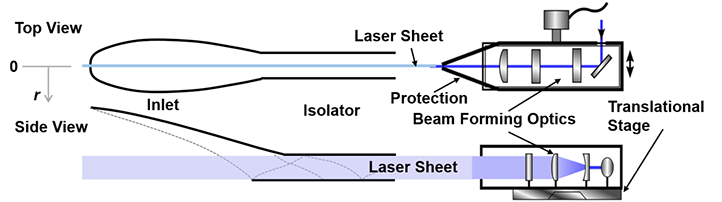

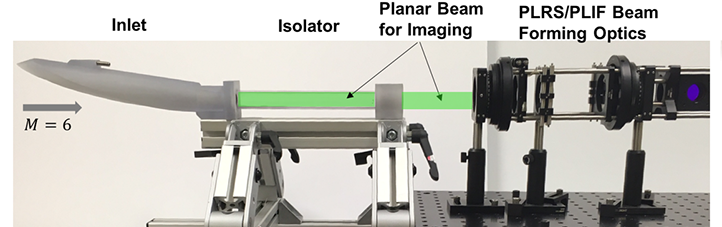

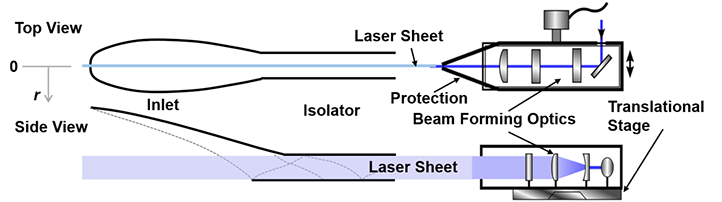

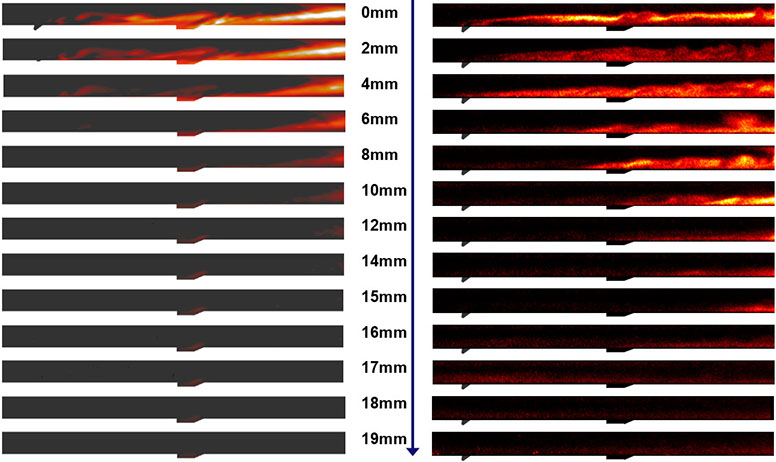

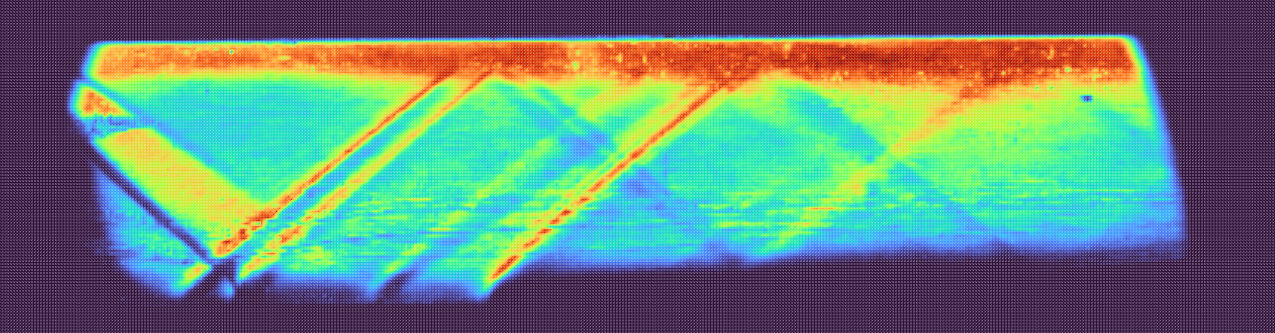

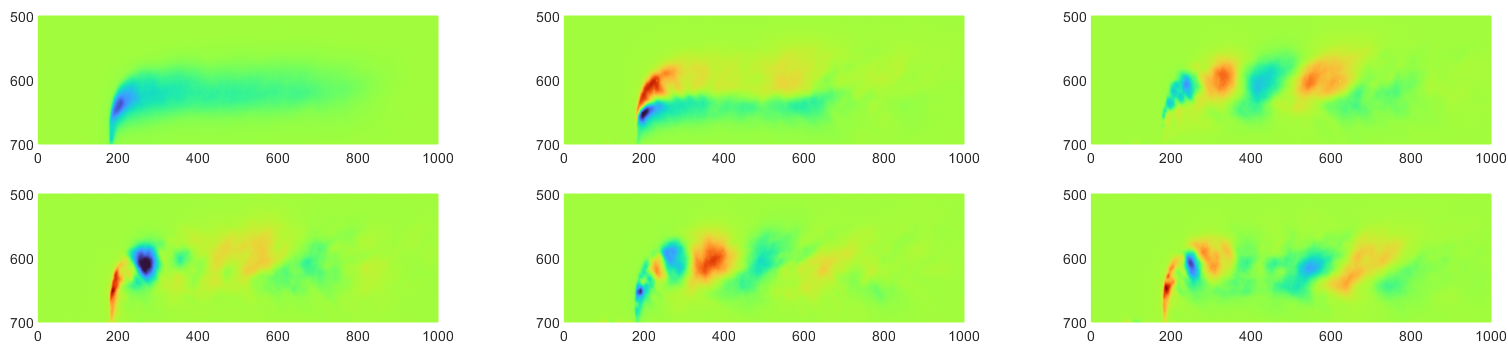

The performance of hypersonic inlets is characterized by metrics such as delivered airflow, total pressure recovery, compression efficiency, and drag coefficient. To estimate the performance of the inlet, PCST structure inside of the inlet and the isolator is usually visualized.

Inlet Unstart and Control

Inlet unstart is a phenomenon that occurs when the airflow through the inlet becomes disrupted, leading to a breakdown in the compression process. When a scramjet inlet is unstarted, the incoming air is spilled. Consequently, the mass flow rate of the captured air decreases, deteriorating combustion, and thus leads to a drastic reduction of the net thrust and engine failure.

Inlet unstart typically accompanies flow choking of the internal flow. For increasing the effective flow area, boundary-layer suction has been proposed. The suction extracts the minimal amount of the mass from the subsonic portion of a boundary layer to eliminate the low-speed region at the cost of small stagnation pressure loss and only a few percent of the captured air. Boundary-layer suctions can prevent inlet unstart and effectively extend engine operation range under certain test conditions.

Supersonic Combustor

The flow residence time in a supersonic combustor is much shorter than those in conventional subsonic combustors. Therefore, better strategies to enhance mixing and combustion reaction are needed to burn the fuel and to operate supersonic combustors. Furthermore, the fuel must be carefully selected such that the ignition delay of the air-fuel mixture could be minimized. As any intrusive measurement techniques would induce additional losses, laser diagnostics are preferred to estimate the performance of the supersonic combustor. Specifically, schlieren, shadowgraph or planar laser-induced fluorescence(PLIF) are often used to visualize the internal flow in the combustor and characterize the flame region.

For airbreathing hypersonic vehicles, the effort to uphold a permittable degree of total pressure recovery limits the flow within the combustor to remain supersonic. Accordingly, the residence time of the fuel in the combustion chamber is inevitably curtailed, limiting the time available for fuel mixing and combustion. On the other hand, due to the high enthalpy flow associated with the flight envelope, the potential thermal damages can incur limitations to the operability of the vehicle. As per such, provided that fuel break up and atomize resourcefully, liquid fuels prove to be multilaterally promising not only for their lower cost and toxicity, but also for their ability to regeneratively cool the vehicle in hypersonic flights.

In a liquid hydrocarbon fueled supersonic combustion ramjet (Scramjet), the combustor performance is mainly determined by the rate and efficiency of fuel atomization, and mixing. Typically, in scramjet engines, the fuel is transversely injected into the combustion chamber from the wall of the combustor, forming complex physical crossflow interactions. Correspondingly, in an effort to study the physical breakup mechanism of jet in supersonic crossflow, plenty of preceding experimental studies opted for optical imaging and spectrometry for their high temporal and spatial resolution, and nonintrusive quality.