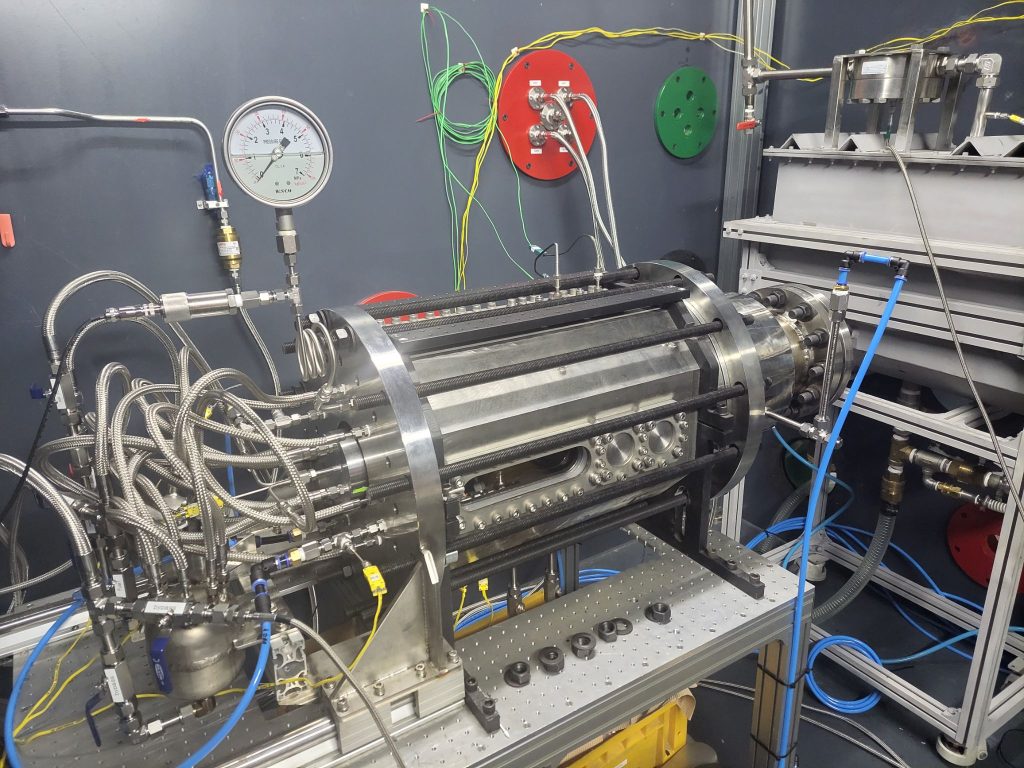

Gas Turbine Model Combustor

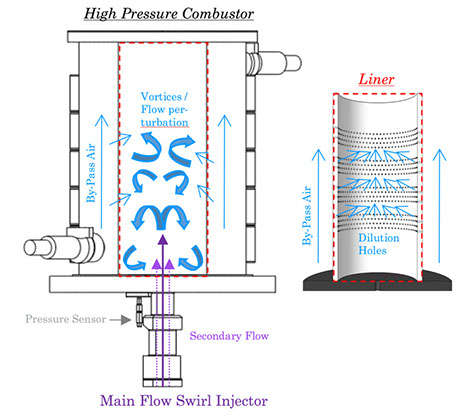

The combustor is considered as a one of the key component of the aircraft engine and gas-turbine power plant. The novel combustion strategies are required to comply with tightening air quality regulations. Lean Direct Injection (LDI) has been introduced as promising technique to reduce NOx emission, noted as major causes of fine-dust in the atmosphere. LDI type combustor burns the well-mixture of the fuel and air in stoichiometric ratio below 1 to decrease the flame temperature. However this flame condition is susceptible to self-excited combustion instabilities which may lead to flame extinction or flashback. Many flame stabilization techniques are proposed and implemented to the gas turbine model combustor in high-pressure condition. The combustor is also being tested to manage fuel flexibility: hydrogen enrichment in natural gas. In addition, the flame diagnoses are on research to measure the reacting flow properties or to investigate precursors of the flame transient to undesirable condition.

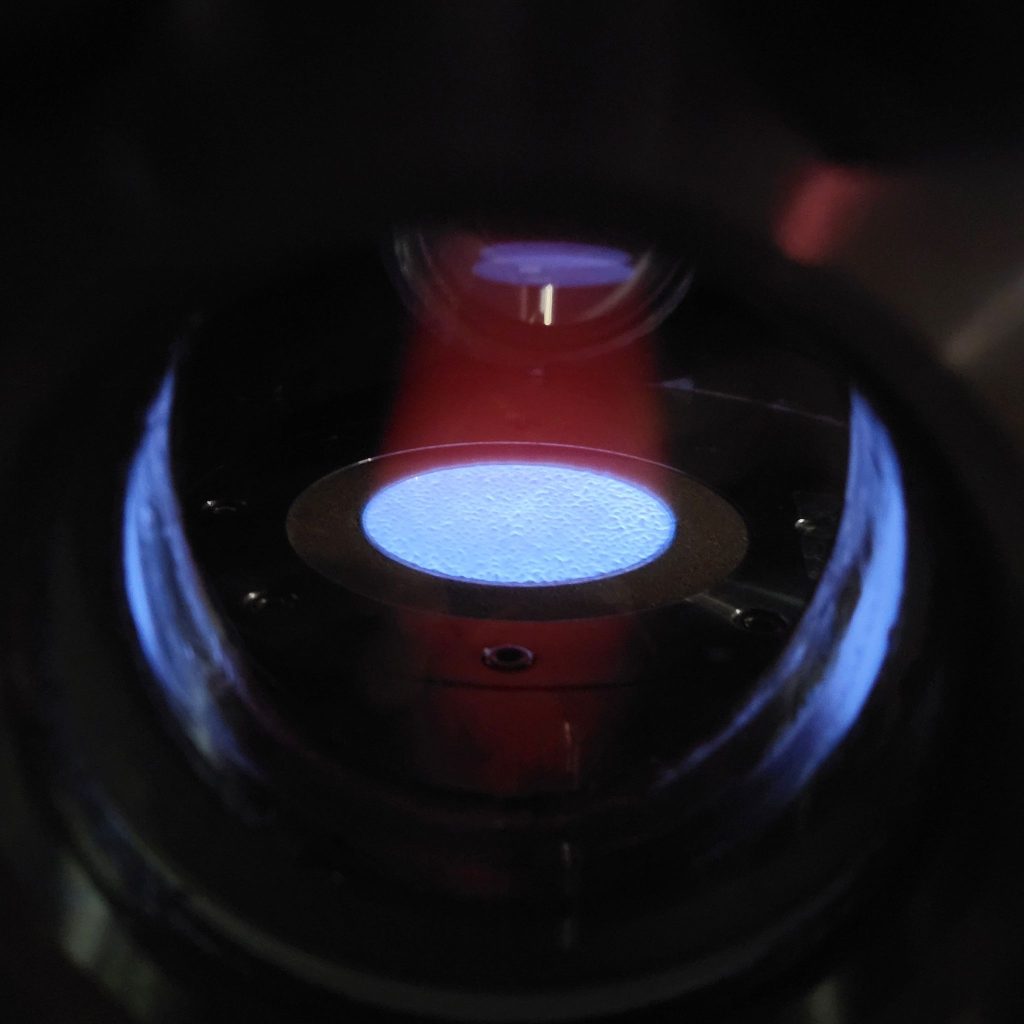

Flat Flame Burner

The Mckenna burner is used to create uniform flat flame above the exit plate. The fuel-air premixed mixture injects through the porous exit material with the uniform flow velocity which is equal to the laminar flame speed. The flame is surrounded by diluted gas from the annular shroud which isolates the flame from the ambient air. Therefore, the flame becomes homogeneous and its condition is determined only from the injection gas properties. The well-controlled flat flame is exploited to validate the proposed laser diagnostics or provides its calibration curve in the high temperature environment.

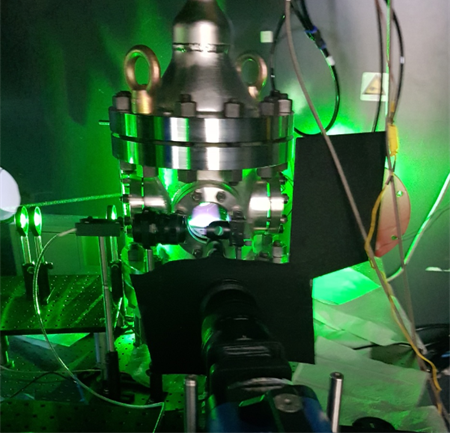

Combustion Instability

Interests in combustion instabilities (CI) and, more precisely, how they may be suppressed with strong acoustic waves emitted from a laser induced breakdown is the focus of our CI studies. It is believed that the amplitude of the peak generated by a strong acoustic source will overpower any present frequencies that are already present in the combustion system. A direct consequence would be a fast change in the heat release rate which as a result would break the energy feedback loop responsible for sustaining CI. High pressure experiments are intended to replicate modern gas turbines’ operating conditions and particularly hydrogen combustion.